White Round Ring PTFE Rings for Sealing

Product Description

Product Detail

All Seals can provide custom O-rings, specially made to your demanding requirements.

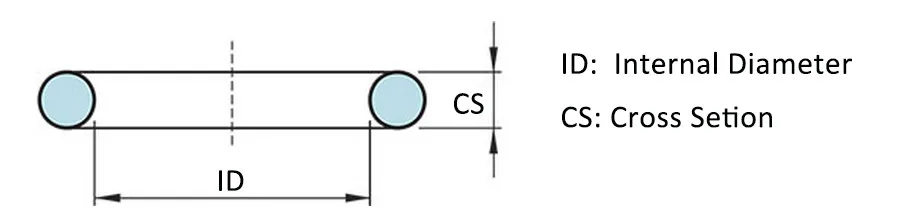

| ID | ≤1000mm |

| CS |

0.3-15mm |

Features:

> Resistant to most chemicals including acids, bases, oils, steam and other chemicals.

> Very tough and abrasive resistant.

> Has minimum friction coefficient of all know pure material

However the material is not easily compressed, and therefore may not seal as easily as some of the other polymers. Its outstanding tear resistance and abrasive resistance result in its slippery surface properties that make it advantageous for use in seals in moving systems such as mass spectrometer probes and valves.

Virgin materials Properties

Filled Materials

Tension strength

Mpa min

> Non-viscous, no aging

> Now molds can be made according to customers requirements.

Properties

Unit

Result

Apparent density

g/cm3

2.10-2.30

Tensile strength(min)

MPa

15

Ultimate elongation(min)

%

150

Working Temp.

℃

-180~260

Melting point

℃

327

Produce Max Temp.

℃

385

Product

No.

Filled compound and content by weight

Ultimate strength % min

Compresive strength MPa min

1

20% glass fiber

10

120

16

2

25% glass fiber

10

100

16

3

20% glass fiber graphile

10

120

16

4

60% bronze

10

80

20

5

15% carbon fiber

11

130

16

6

24% bronze 12%glass fiber 6% graphite

9

100

16

7

15%glass fiber 105polyikmide 5% graphite

10

120

16.7